Processing

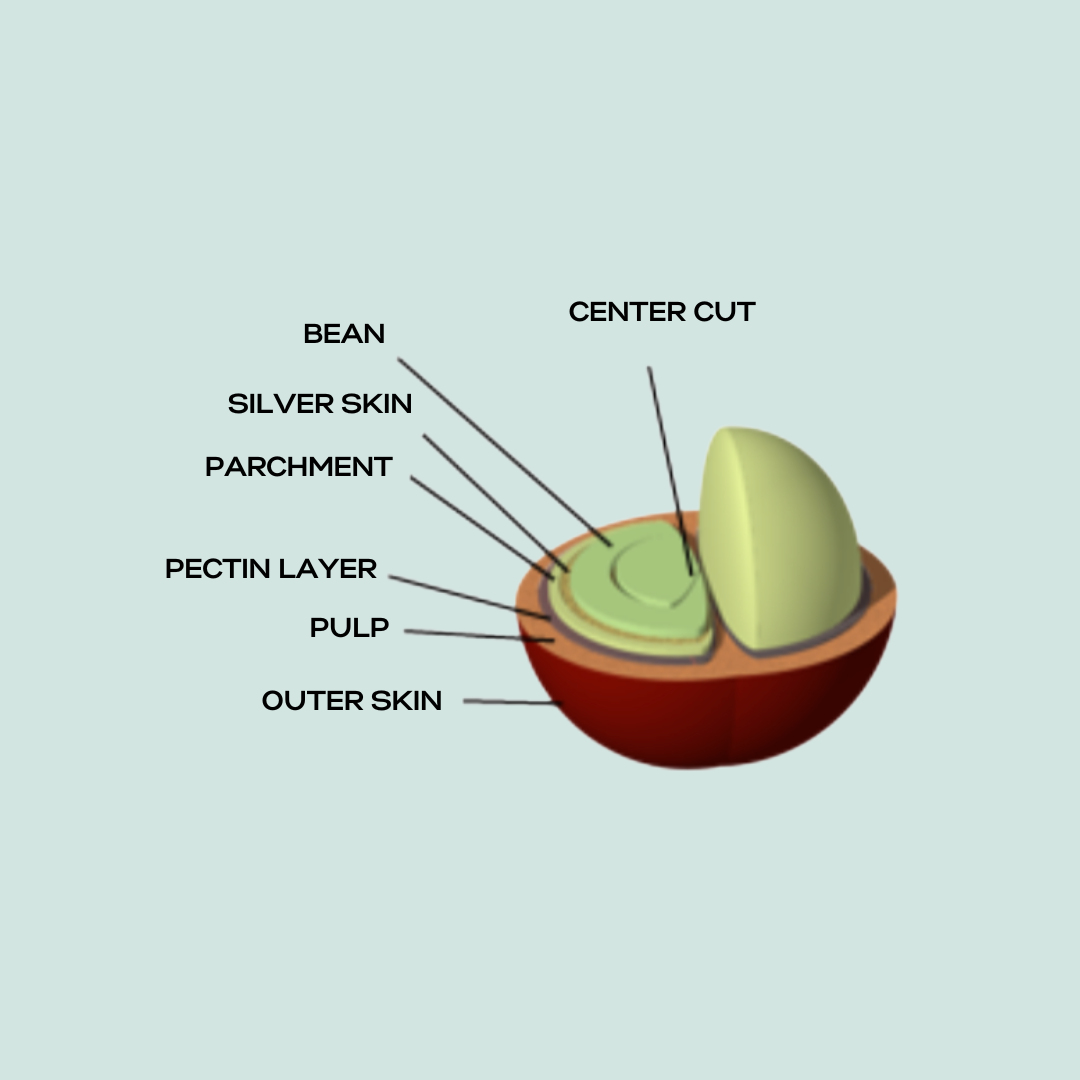

There are so many processes being employed globally to the coffee cherry after harvesting. These processes have a major impact on the flavour profile of the bean. Once the ripe coffee cherries are picked; they must be processed quickly to extract the seed, which is the green coffee bean, preferably within eighteen hours or less in order to avoid off- flavours. A thin membrane called the silver skin covers the seed, along with a parchment, the pergamin, which separates it from the fleshy pulp. Then there is the outer skin, which covers the pulp.

All these layers must be stripped off the seed while leaving the seed itself intact. This is generally done by one of two processes: the dry process, also called the “natural” process, or the wet process.

Washed

In this process, water is the emphasis. The coffee cherry is brought to the wet mill where it is then pulped (outermost fruit skin is removed). Next it is put in water with any floaters being discarded as defects. Then, the coffee is fermented (fruit mucilage layer broken down), washed to remove the remaining fruit, and then dried on a patio, raised screen bed parchment stays with the green bean until it is milled at the dry mill. With this process, the coffee tends to have flavor characteristics that are brighter, a cleaner cup, and a lighter body. Some of the countries known for their washed coffees are Indonesia, Ethiopia, Brazil, and Yemen.

Natural

Natural processing is the original method used for coffee that consists of more hand labor than machinery. There are higher risks of defects due to handling, drying, and hand sorting. The coffee cherries are picked and then directly dried under the sun or on raised screens as full cherries. Once the cherry is dried, it turns into a dark brown pod that is hard to the touch; the green seed is taken out, leaving the other layers behind. Because this process is so hands on and the defects can only visibly be accounted for, there is large room for error; greater chance of defects, taints, and a lack of uniformity in roasting in cupping occurrences. While there is more room for error, natural processed coffees tend to have more body and lower acidity than their washed counterparts.

Pulped Natural

During this process, the skin is removed from the coffee cherry, leaving the fruity mucilage intact during the drying process. The machinery used to eventually remove the mucilage is either pulped or taken off by forced demucilage equipment. Pulped natural coffee can have more body and lower acidity than the washed process, and a cleaner, more uniform cup than the natural process. The dry process is common in Brazil and drier parts of Africa. In general, the wet process, which is more resource-intensive, is used in India and water-abundant countries in Africa. In India, there are water purification standards that require all of the water to be ponded, regenerated, and reused. There are settling ponds, which are treated with enzymes. Ultimately, it is important for a roaster to have very good relationships with their sources for beans and assured knowledge of their processing techniques. The harvesting and processing will affect the flavour of the coffee dramatically and guides the roaster’s decision making thereafter.

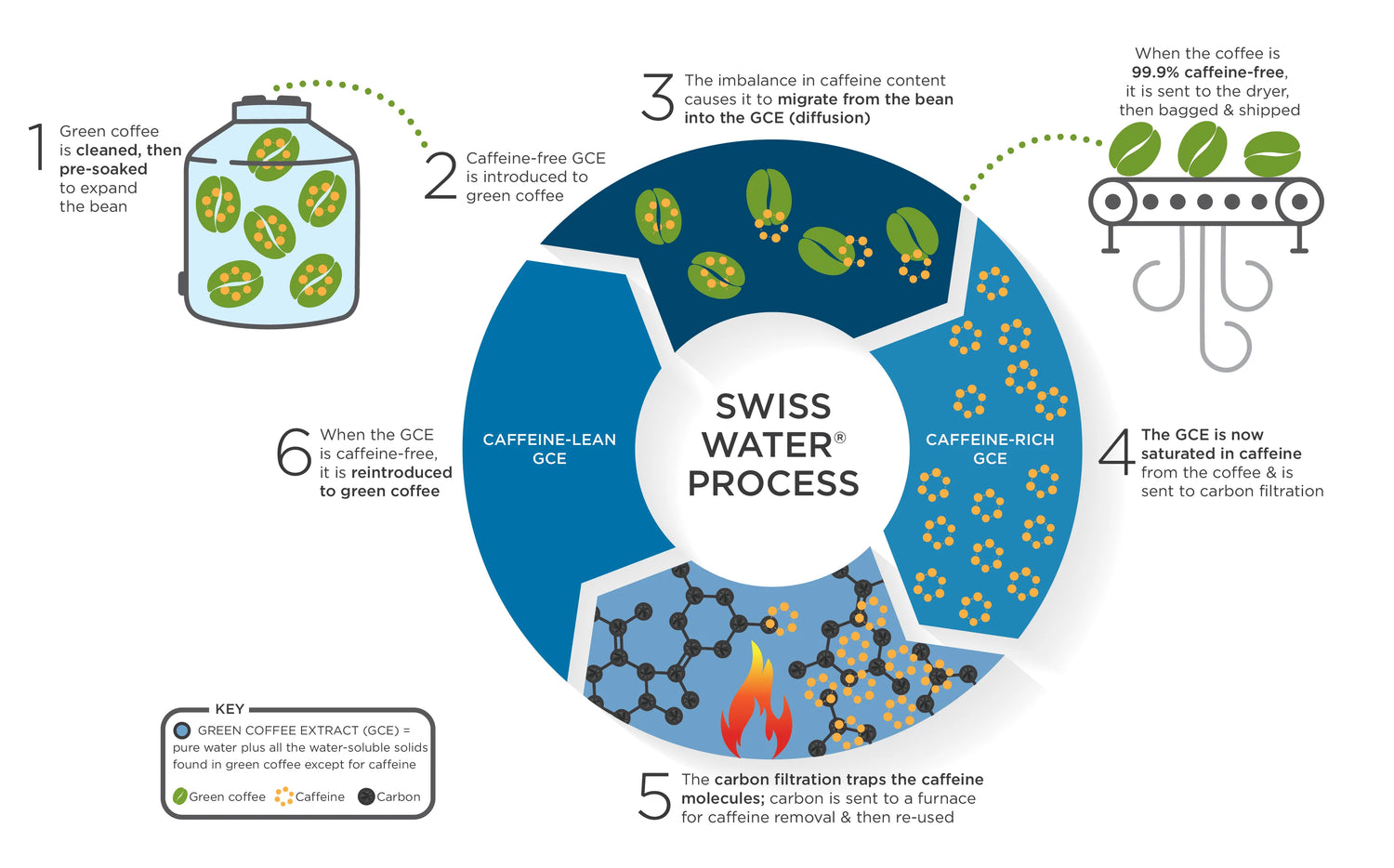

Swiss Water Decaffeination Process

The water process uses flavour-saturated water as a solvent to remove caffeine. First, a batch of beans is soaked so that all the flavour compounds dissolve in the water. The caffeine is removed from that water with activated charcoal. Then the first batch of beans is thrown out, and the water is combined with a new, untreated batch of beans. Since the water is already saturated with every dissolvable compound except for caffeine, only the caffeine in the beans will dissolve, leaving the flavour intact. However, since the water is used over and over, some flavours may become commingled between batches. The most well-known variant of this is the Swiss Water Process, the first economically viable water decaffeination process and the current industry leader. The company asserts that it has made substantial improvements to reduce the cross-batch contamination phenomena, to the point where it is not an issue.